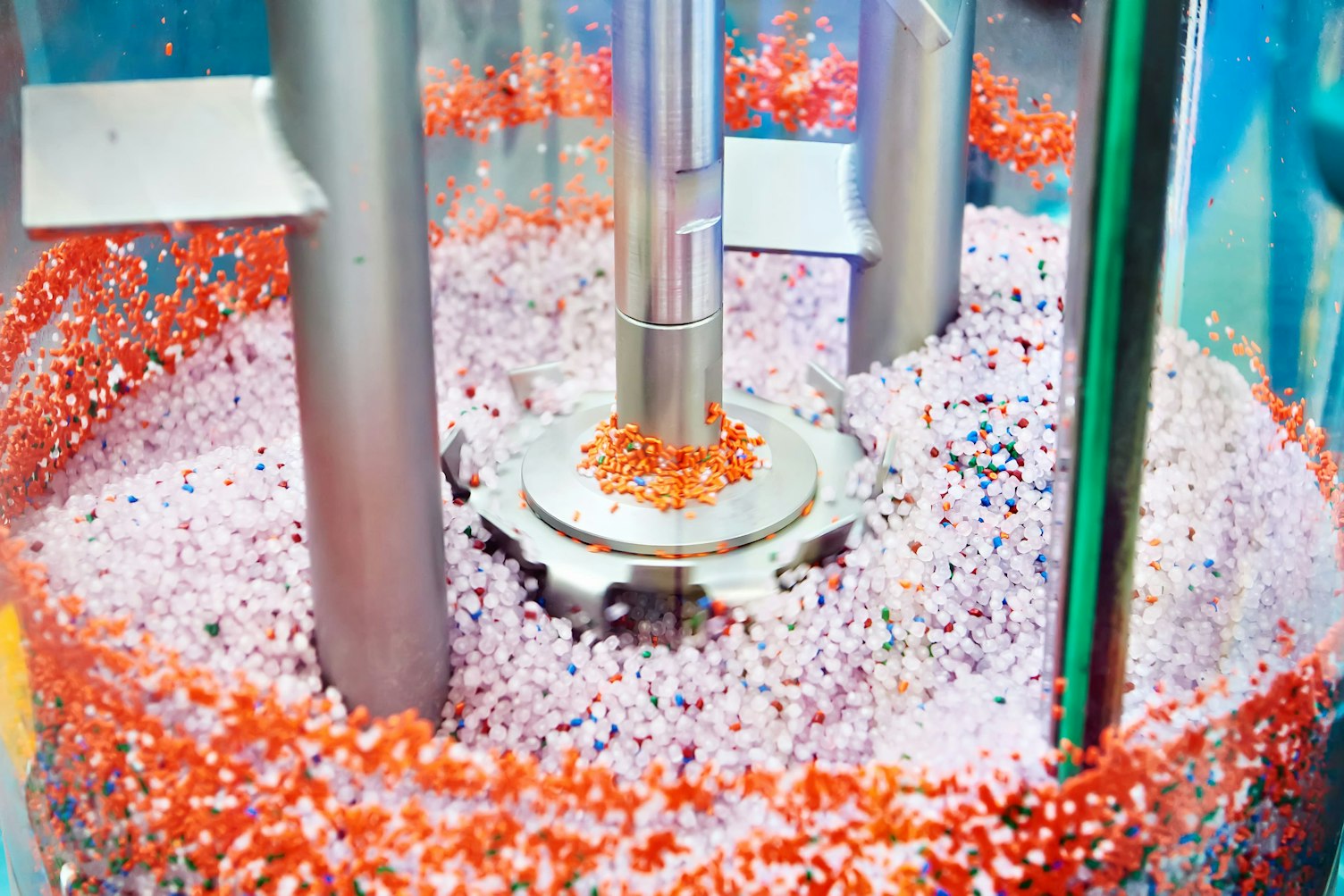

Pellet loss is the second-largest source of primary microplastics in the marine environment. As the plastics industry has direct control over pellet loss, Plastics Europe and EuPC launched the European certification scheme integrated with Operation Clean Sweep® (OCS).

The OCS program helps companies tackle pellet leakage by providing key recommendations based on six pillars:

- Improving workplace configuration to prevent and respond to leaks

- Establishing internal procedures to achieve zero loss of plastic materials

- Providing training and accountability for employees

- Conducting regular audits

- Ensuring compliance with the law

- Raising awareness among value chain partners

By signing the European OCS pledge, your facility can incorporate plastic-loss prevention into its strategy. As an approved OCS Europe Certification body, we provide third-party audits, which, when passed, award your facility the OCS Europe certificate and a listing on the OCS Europe public register of certified companies.

Benefit from OCS certification

OCS certification validates your company's commitment to environmental responsibility and sustainability reporting strategy.

Implementing the OCS program in your facility enables you to:

- Contribute to water quality and wildlife preservation

- Comply with state regulations

- Ensure effective safety and housekeeping programs

- Safeguard employee safety

- Improve operational efficiency

- Enhance profits

- Secure your reputation in the community

How does certification work and what is the process?

- Stage A:

We provide a proposal tailored to your organization for acceptance before the audit process begins.

- Stage B:

We perform the first part of the audit – a documentation review to check if your system complies with OCS requirements.

- Stage C:

We perform the second part of the audit on-site to confirm OCS implementation. Discussions with employees ensure processes align with OCS requirements and documentation. Audit results are presented, including strengths, weaknesses, nonconformities and opportunities for improvement. If nonconformities are found, you have 30 days to submit a corrective action plan for our assessment.

- Stage D:

Annual surveillance audits are conducted over a three-year certification cycle to verify that initial certification conditions are maintained and to ensure continuous improvement through your action plan.

- Stage E:

Every three years, a recertification audit is performed on-site to verify that the conditions for the initial OCS certificate are still met.

Independent OCS audits from an approved certification body

As the world’s leading certification, testing, verification and inspection company, with technical competence in the plastic sector, we offer independent third-party audits accredited by OCS Europe. Our global, multi-disciplinary network of experts can help your company ensure compliance with requirements on the prevention of plastic pellets, powders and flake loss.

Inward Way,

Rossmore Business Park, CH65 3EN,

Ellesmere Port, Cheshire, United Kingdom