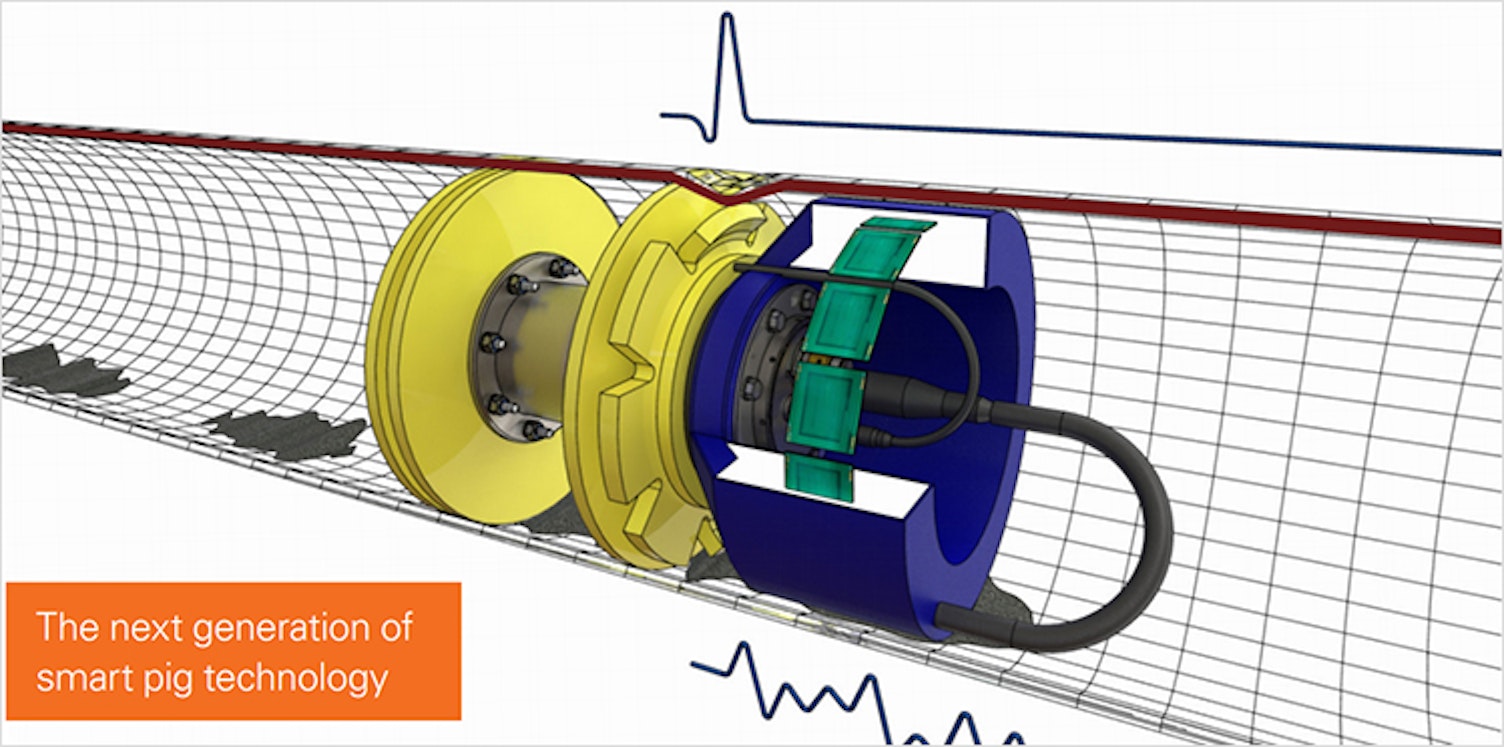

Pipelines are a safe, efficient method for conveying high value commodities, such as oil and gas. However, they are vulnerable to factors such as corrosion and deposits, which can reduce flow rates and cause expensive failures. Currently, to ensure pipeline integrity, cleaning pigs are used to remove deposits, and then intelligent in-line inspection (ILI) pigs are used to detect defects. Conventional ILI inspections cannot be performed frequently, as they are costly and disruptive. This means that pipelines can become susceptible to failure during the long period between inspections. Our smart pigging solutions enable your pipeline to be monitored for defect growth on a regular basis, minimizing costs and reducing risks to your operation.

Challenges of Pipeline Maintenance

Pipeline failure can negatively impact production, harm the environment and endanger lives. The high cost of failure means that operators are more dependent than ever on pipeline inspections. However, it is often difficult to use conventional ILI inspection methods, for example, when large sections of pipeline have complex geometries that are situated in hard to reach environments. As conventional inspections can be disruptive, pipelines often go without inspections for years at a time, increasing the risk of failure.

12FL, Chongryong Bldg., 257, Hangang-daero, Yongsan-gu,

04322,

Seoul, Korea, Republic of