During the lifetime of a vehicle, its components, parts, assemblies and sub-assemblies will need to withstand repeated usage as well as conditions including stresses, strains and temperature changes. For this reason, original equipment manufacturers (OEMs) demand the highest quality components throughout the supply chain.

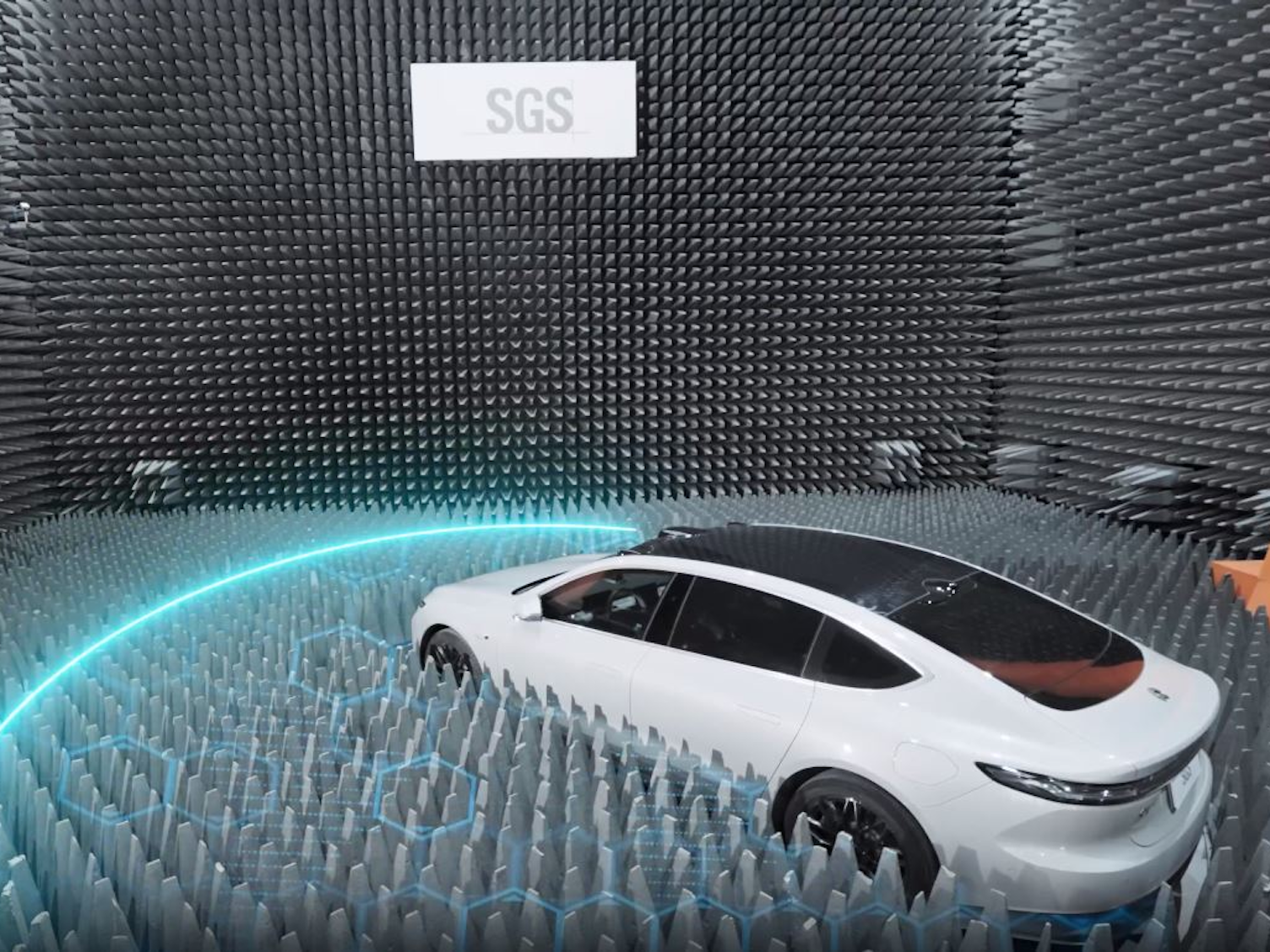

At SGS, our endurance and durability testing services can verify these high standards and help OEMs determine the expected life expectancy of components, as well as the long-term viability of the car. Testing during the early stages of product development also detects faults before the vehicle goes into production, saving time and costly recalls.

We have the experience, equipment and expertise to test full vehicles, subsystems and individual components against OEM national specifications such as ASTM, DIN and JASO, as well as international standards including ISO, EN and SAE.

Durability and endurance testing

To check the durability of interior and exterior parts we use endurance benches or robots to perform fatigue tests by applying alternating or cyclic stress or strain at high, low and room temperature. Endurance can be assessed under three categories: static strength, dynamic strength and stiffness.

Durability and endurance testing on the following vehicle parts, assemblies and systems:

- Life and fatigue test

- Chassis, including the hydraulic servo system

- Interior, including cockpits, instrument panels, door panels, center and floor consoles, decorative interior panels and trim parts, glove boxes, air louvers, grab handles, leather and textile panels, soft-touch panels, decorative trim, trunk liners, A/B/C pillar covers, pedal box assemblies, seats, steering systems, sun visors and grommets

- Exterior, including bumpers, front end modules, front grills, spoilers, front-end carriers, window sealing strips, water deflectors, air inlets and air ducts, door handles, plastic body parts and panels, roof rails, headlamps and rear lamps, under-bonnet products, air intake manifolds (plastic) and engine covers

- Body test

- Electric rear mirror adjust test

- Window regulator test

- Armrest force test

- Door handle/grip test

- Endurance test of gearbox, springs, brake pedal, suspension system and steering

- Four doors, hood and decklid

- Side door key life test

- Open/close inside/outside

- Hood fatigue endurance test

- Electric/manual tailgate fatigue

- Fuel lid life test

- Spoiler durability

We test to the following standards:

- Q/CHJ 3 C31 001

- Q/CHJ 3 C10 020

- Q/LIA3C25005

- Q/LiA3C10020-2022(V4)

- Q/LiA3C00019-2021(V1)

- Q/LiAC25001-2022(V3)

- Q/LiA3C31001-2022(V3)

- PR 281_2017

- QJ XP 03BZ.002-2020

- QJ XP 03BZ.301-2021

- QJ XP 03BZ.005-2020

- QJ XP 03BZ.013-2018

- As per OEM/customer specification

Why choose SGS endurance testing services?

We are the world’s leading testing, inspection and certification company, with laboratories, testers and industry experts located throughout the world. Wherever you are, we can ensure your materials, parts and vehicles meet all the required standards.