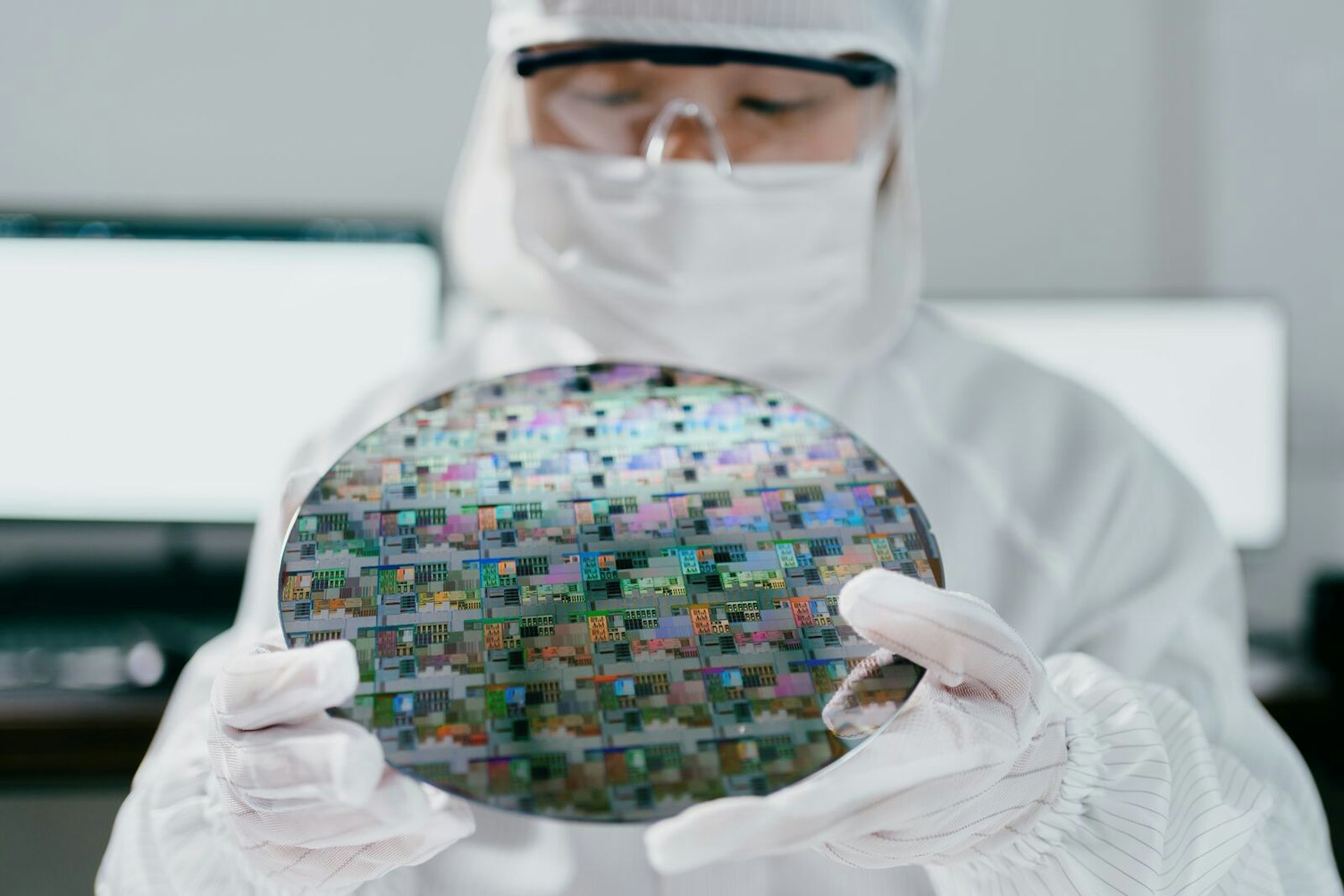

Understanding and identifying the causes of semiconductor failures are crucial for improving the reliability and performance of electronic components. Our failure analysis services pinpoint the location and type of failures under a wide range of circumstances. Our team offers professional consultation backed by extensive field experience, providing valuable insights on the latest technical trends to ensure reliable results.

Ensure your semiconductor components meet the highest level of reliability standards requirements

We enable you to:

Identify failures accurately

Pinpoint the exact location and type of failures using advanced analysis techniques.

Gain valuable insights

Benefit from professional consultation and in-depth analysis to improve your products.

Enhance reliability

Improve the reliability of your semiconductor components through comprehensive failure analysis.

A comprehensive range of failure analysis services

- Non-destructive failure analysis:

- Microscope

- X-ray

- Scanning electron microscopy with energy dispersive X-ray spectroscopy (SEM/EDX)

- Scanning Acoustic Microscopy (SAM)

- I-V curve tracer

- Photon emission

- Thermal emission

- Destructive failure analysis:

- De-capsulation

- Delayering (chemical etching/reactive ion etching)

- Cross-section

- Ion milling

- Focused Ion Beam (FIB)

- Cross-section/circuit modification

Failure analysis expertise and advanced techniques

As the global leader in inspection, certification and testing, we provide unrivaled expertise in failure analysis. Our dedicated professionals use advanced techniques and a systematic approach to deliver accurate and comprehensive results. We conduct both non-destructive and destructive failure analyses, meticulously executed to ensure the highest level of accuracy.

Ready to enhance the reliability of your semiconductor components?

Contact us today to learn more about our failure analysis services and how we can help you achieve accurate and comprehensive results.