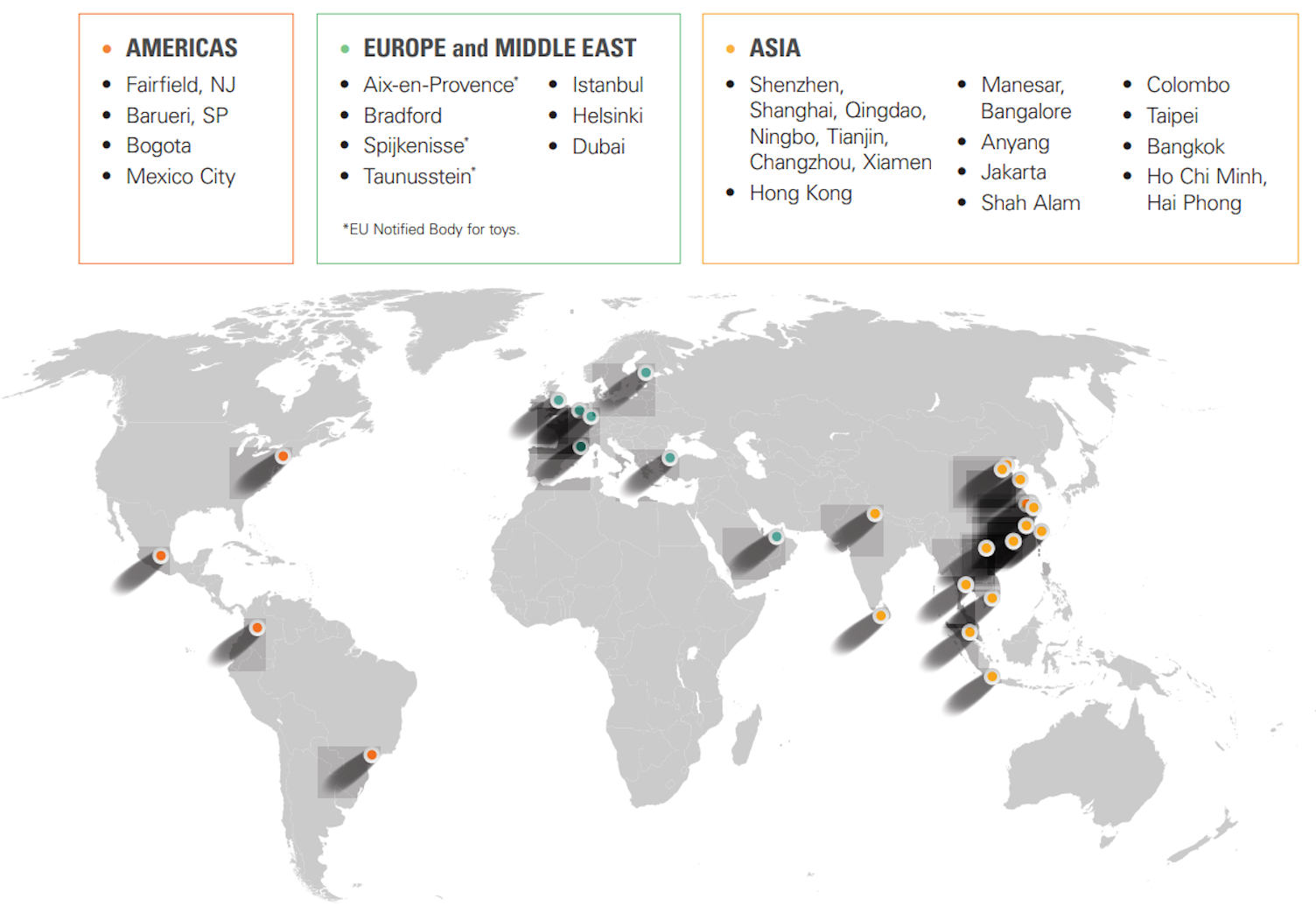

Toy suppliers – manufacturers, retailers and importers – must ensure that toy products meet regulatory and client-specific requirements for safety and quality. Our global network of testing facilities, staffed by knowledgeable and experienced personnel, can smooth a product’s route to market.

Our cost-effective testing services enable you to:

- Reduce risk

- Shorten time to market

- Demonstrate product quality and safety

Our toy labs are strategically located in key manufacturing zones and transit points. They are internationally recognized by major industry associations, accreditation bodies and authorities including:

- IAS (US)

- NABL (India)

- CNAS (China)

- COFRAC (France)

- DAkkS (Germany)

- HOKLAS (Hong Kong)

- UKAS (United Kingdom)

Chemical testing

Applicable to all toys made of plastics, wood, textiles, our chemical test services can verify that toys do not contain any banned or restricted chemicals, or dangerous materials. We test for chemicals, which could be dangerous if a toy is swallowed or chewed, including:

- Heavy metals – lead content, cadmium

- Phthalates on plastic toys – softeners

- Azo dyes on textiles

- Formaldehyde emission from wooden toys

- Nickel release during prolonged contact with skin

- Organic chemical compounds

- Carcinogenic, mutagenic and reprotoxic (CMR) chemicals

- Endocrine disruptors

This list is not exhaustive. Contact us for the full range of our capabilities.

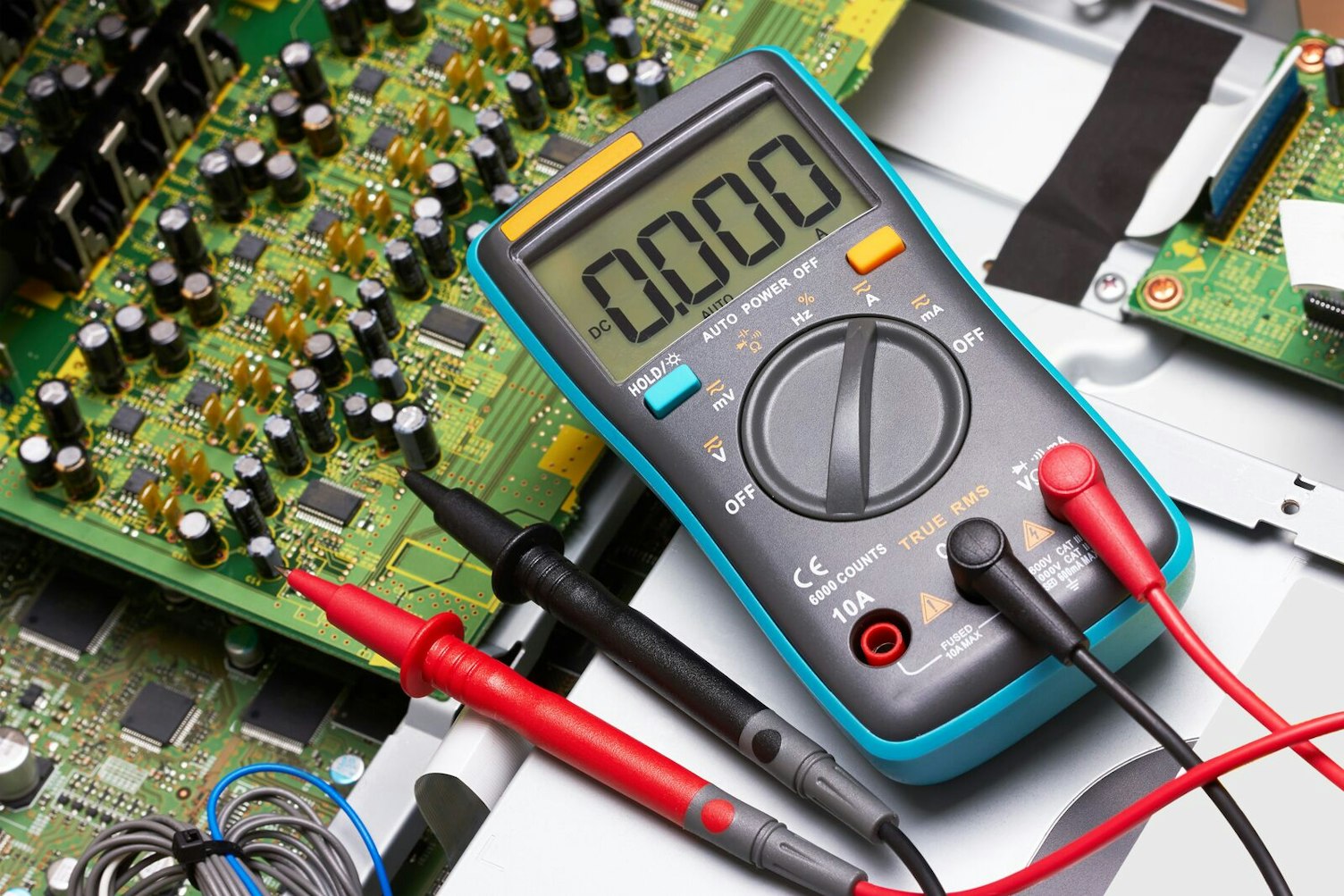

Electrical safety testing

Ensuring the safety of electrical, radio-controlled and battery-powered toys and devices we offer range of tests to assess electrical safety:

- Resistance to heat and fire

- Short-circuit

- Labeling

Contact us for the full range of our electrical safety tests.

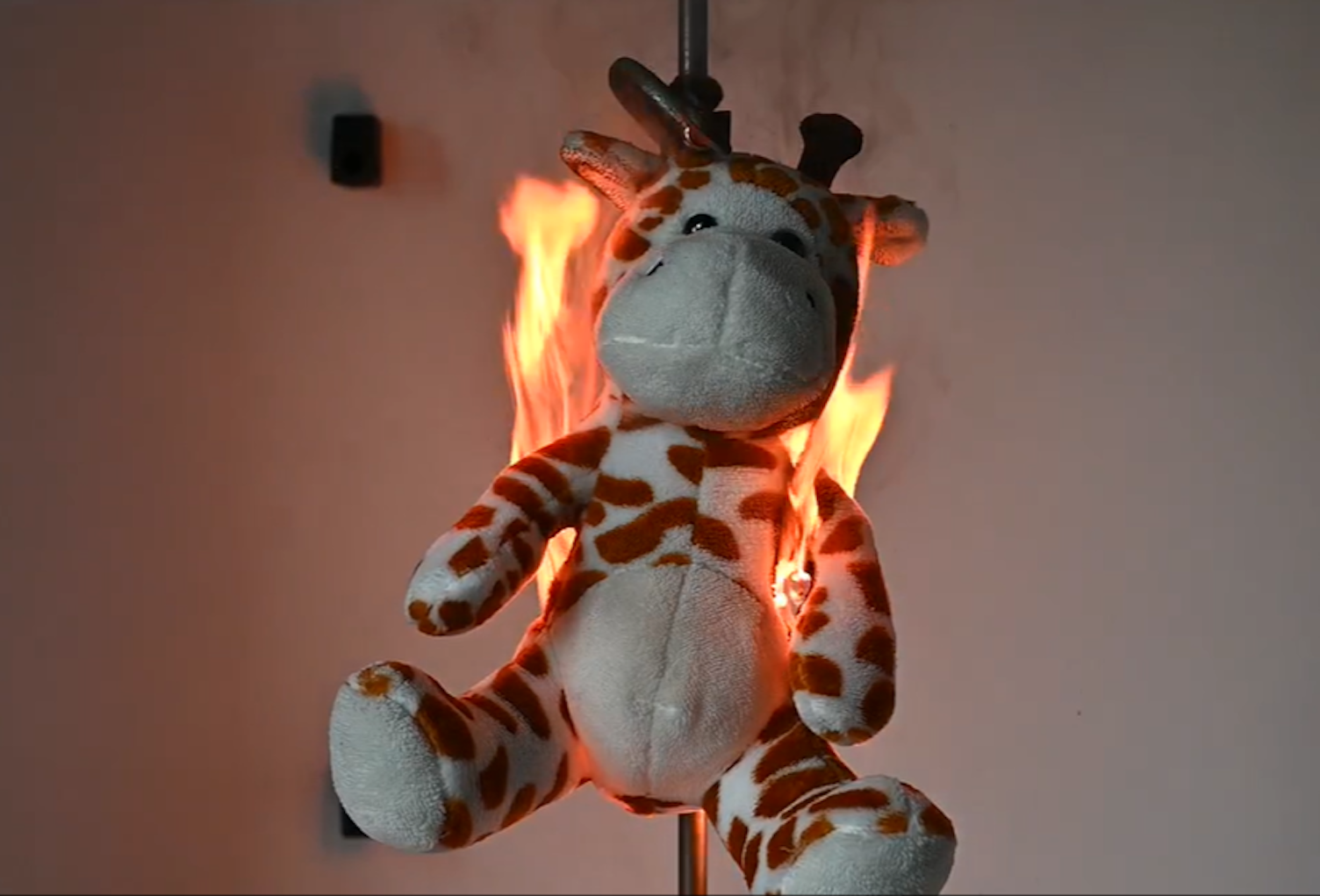

Flammability testing

Conducted on all toys made from textile fabrics, soft toys and plush toys, our flammability testing for toys ensures that if a toy does catch fire the user can drop it or climb out of it before serious injury occurs.

Certain flammable materials, that pose the greatest risk, are prohibited from all toys.

Mechanical/physical testing

We can test all toys to ensure there are no hazardous sharp edges, sharp points and small parts, or other potential hazards, as well as tests for:

- Strength

- Fatigue

- Durability

- Tensile

- Torque

- Static

- Impact

- Noise tests

This list is not exhaustive. Contact us for the full range of our capabilities.

Added value testing for toys

Covering every aspect of toy design, development and safety, we offer a range of support services during the product design, development, production, distribution, store and use phases:

Safety assessments

Chemical safety assessments

Failure analysis

Labeling reviews

Documentation review/validation

Product line reviews

Technical assistance

Age grading evaluations

Consultancy

Training

Design evaluation

Complaints evaluation

Packaging testing

Sustainability and the SGS Green Mark

The toy industry must also consider legislation that is not specific to toys, such as:

REACH

Food contact materials (FCM)

Classification, labeling and packaging (CLP)

Electromagnetic compatibility (EMC)

Radio equipment directive (RED)

Restriction of hazardous substances (RoHS)

Consumer product safety improvement act (CPSIA)

Persistent organic pollutants (POP)

As well as requirements for:

Batteries

Cosmetics

Microbiological testing

Packaging

Country club estate building 9, 21 Woodlands drive,

2191,

Woodmead, South Africa